What does it do, and how?

Briefly, the VOES is a device to control the ignition advance - this is

necessary to avoid detonation. Real detonation can destroy your engine - you

can read about it

here.

Knowing about deto will help you understand the VOES function.

Now, low vacuum (the term "low vacuum" describes a state in which pressure in

the intake tract is relatively closer to normal atmospheric pressure) is not

what causes detonation, but low vacuum is an indicator of conditions that lead

to detonation. We can use it to tell us to change the situation, by increasing

our RPMs for instance (with a downshift, which increases the vacuum), or

rolling off the throttle (which reduces our speed), or an electronic

ignition can use the low vacuum to operate a switch to tell the black box to

change the ignition parameters.

And that is what the VOES does - it detects high vacuum

and tells the black box to advance the timing.

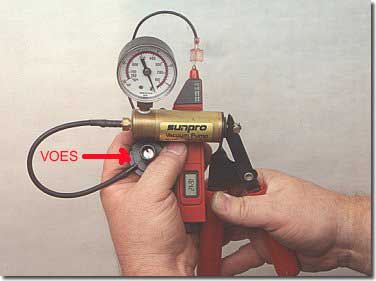

The VOES is connected by a hose

to a fitting on the intake manifold or carburetor. Inside the

VOES is a diaphragm, a spring, and a set of electrical contacts. The switch

has only two positions: on, and off, and they are selected by vacuum through

the hose pulling the diaphragm up and turning the switch ON, or the spring

pushing it back to OFF.

The switch selects one of two ignition maps in the black box - there is no

in-between; it's either OFF, and the timing is retarded, or it is ON with the

timing advanced.

The normal (default) position is OFF/RETARDED. That is the position you want

for starting, acceleration, and high-load operations like going up a hill in a

gear that's too high. It is also the position you want

it to go to if the switch fails or the vacuum hose breaks or leaks.

When a measured amount (more on that later) of vacuum is applied to the switch

the

diaphragm lifts, turning the switch ON, which switches the black box

to the advance curve. When the vacuum drops again, the spring pushes the

diaphragm

back down, and the switch returns to OFF, its default position. There are only

two positions, ON or OFF, and there are only two ignition maps (in the Harley

box), retarded or advanced.

(There. I've said that twice now, and I might say it again just to make sure

everybody understands, since I just know you're not taking notes.)

Are there different VOES settings for different bikes?

Yes. Think about it. The heavier the bike and the smaller the engine in

relation to the bike's weight, the wider you will have to open the throttle to

develop or hold the speed you want without downshifting. That's the formula

for detonation. The

vacuum level will be

dropping waaaay down and the ignition needs to be retarded. Make the bike

lighter or increase the engine size or downshift and

you won't have to open the throttle so far to get the power you want - the

vacuum will stay higher, and the ignition can stay advanced.

What that means is that the VOES for a bagger will be set to advance the

ignition at a stronger vacuum level (that's a higher number of inches of

mercury) than the VOES on a Softtail that weighs over a hundred pounds less,

even

before you load the bagger up with the old lady and a week's worth of camping

gear.

Take that bagger and gear; they're at a traffic light on the way out of town.

Sitting there idling the throttle is nearly closed, so the

vacuum is strong - a high number, so the spark is advanced at idle - about 30

degrees if you use a Crane Hi4 ignition with the advance curve selector set in

the middle.

Now roll the throttle open to

pull away and the vacuum drops. The RPMs are still low and they

build slowly because of the weight, so vacuum stays low. The VOES, responding

to the low vacuum, switches OFF, retarding the timing to about 10 degrees

(again, Crane Hi4) while still at idle speed.

As RPMs build and enough vacuum develops, the ignition throws in more advance -

by 3,000 RPM with the throttle rolled off enough to hold that speed, you'll see

about 35 degrees of advance. The Crane box will allow even more advance - with

a

steady throttle (high vac) at 4,800 RPM you'll see nearly 40 degrees of

advance. You don't want the bagger's ignition to advance too soon, though, and

induce detonation.

Now let's have some 130 pound chick on an FXR pull away from that light.

Her engine's not going to require full throttle to pull away smartly, and even

if she gives it full throttle the RPMs will build fast, developing

vacuum quickly. For that bike we can set the VOES to go to full advance at a

pretty low level of suck, and the VOES will quickly advance the

timing.

What the hell is that?

What the hell is that?